TELEDYNE — Airline Data Communications

THE CHALLENGE: CREATE A SOLUTION TO PROTECT THE HANDHELD TELEDYNE DATA-LOADING SYSTEM.

Electronics in aviation and ground control are often subject to harsh conditions, so the challenge for PTI Design was to create a safeguard solution for the Teledyne Data-Loading System. This solution included an external protective bumper and grip system, along with a detachable carrying handle and tethered cap for protection of the data cable port when not in use. Every stage of PTI Design’s process was utilized to provide a complete design solution for Teledyne, providing all of the necessary components for manufacturing by PTI Engineered Plastics.

DESIGNED TO PROTECT

DESIGN SOLUTION: PHASE I

Combining ergonomics and product durability all in a single design solution.

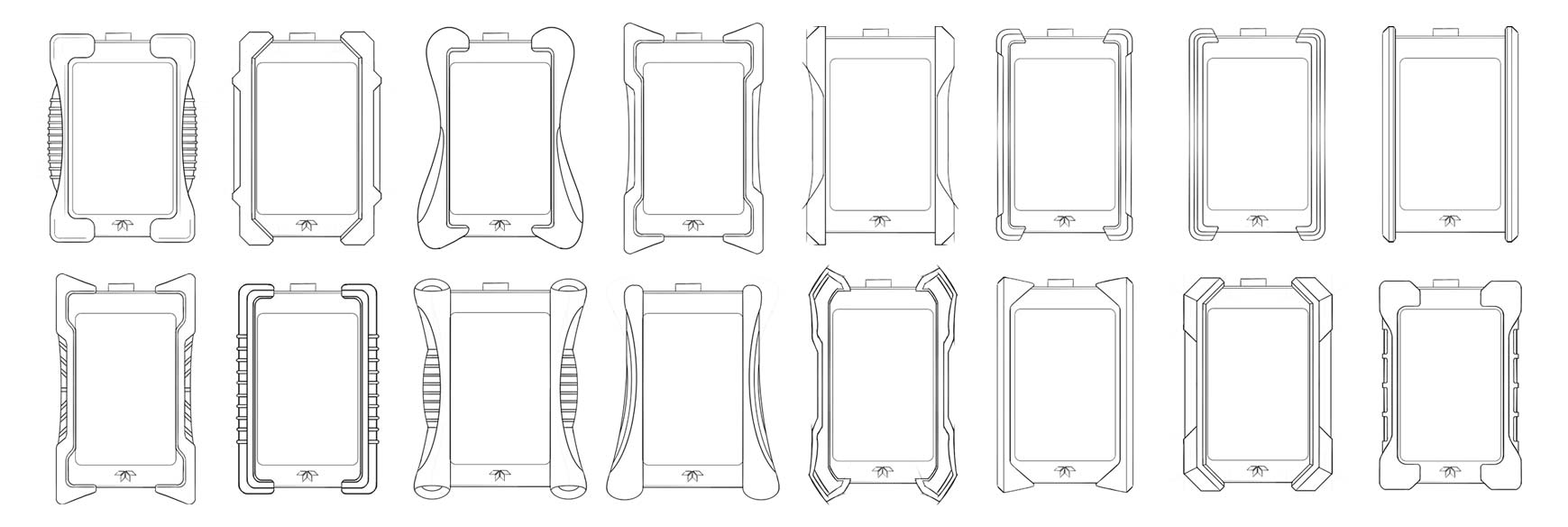

As with any handheld device, securing a solid grip is crucial to prevent accidental dropping, so we began with a number of handle configurations suitable for a variety of hand sizes. We then focused on protecting sensitive areas, such as exposed corners, to reduce potential damage in harsh environments.

DIGITAL DEVELOPMENT

DESIGN SOLUTION: PHASE II

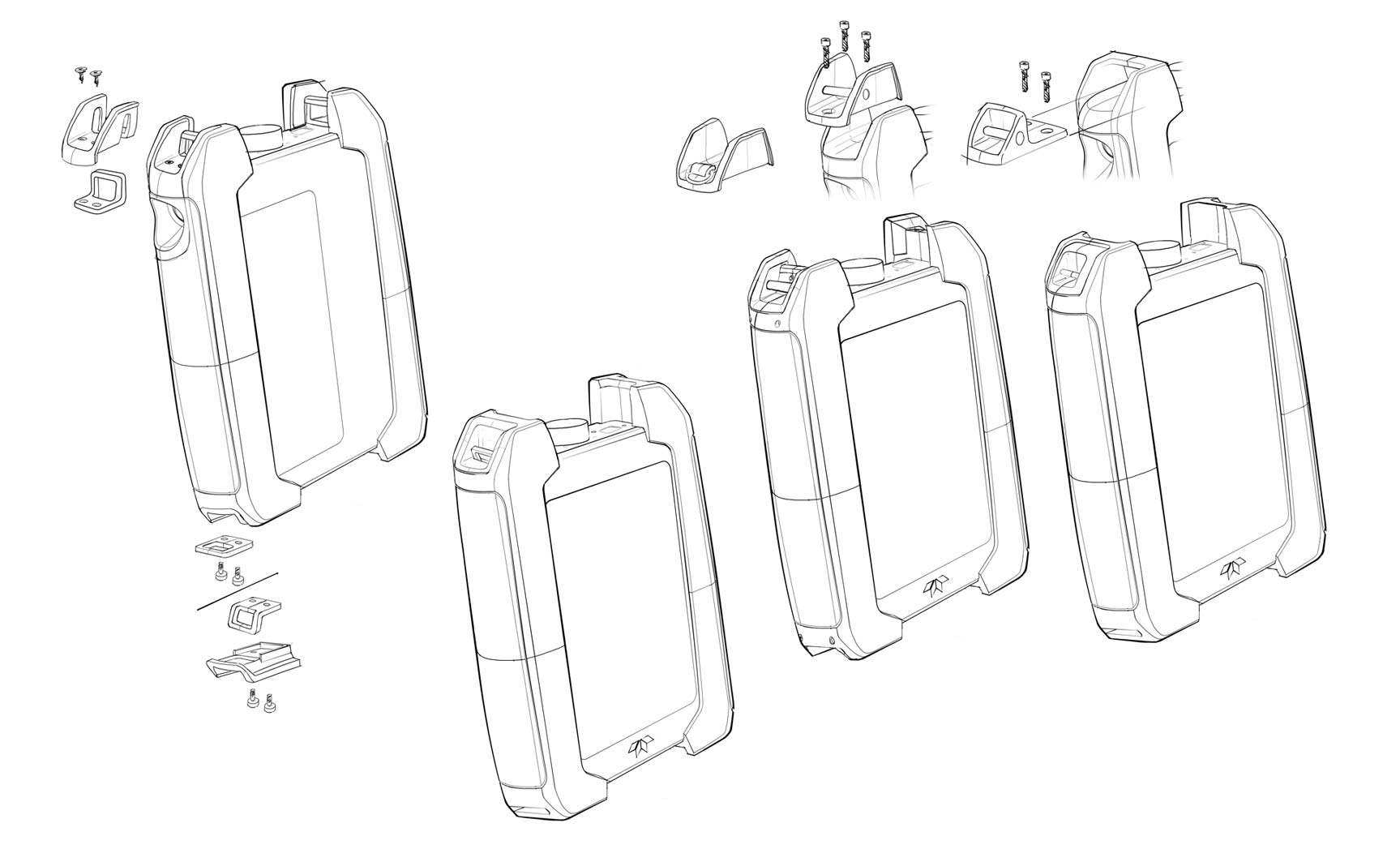

Digital 3D renderings offer a unique opportunity to explore color, materials and finishes (CMF).

Our design team developed a variety of digital renderings to study preliminary aesthetic options that align with the product / brand’s Visual Brand Language (VBL). Here we explored Color, Material and Finish (CMF) options to provide a number of design themes that may be applied.

PROTOTYPES

DESIGN SOLUTION: PHASE III

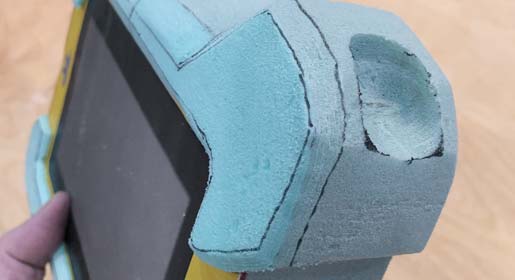

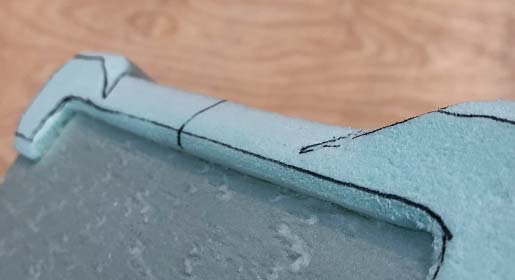

We offer a range of prototypes from hand-carved foam to 3D printed models.

Our designers are artists capable of carving working prototypes from various types of modeling foams. This is a great technique to quickly iterate and understand your product firsthand, providing proof of concept for ergonomics, fitment, and assembly techniques. Once refined, we translate these findings into 3D models that allow us to hone in the overall form and proportions of the product design and provide a functional proof for manufacturing reference.

FINAL PRODUCT DESIGN

DESIGN SOLUTION: FINAL

PRODUCT PROTECTION BUMPER GRIP DESIGN

The Teledyne bumper and strap design was deployed and has received great feedback from the field. Users have reported that the unit is much more comfortable to use with little fear of dropping during operation. The customer shared their appreciation for the design and integrated branding, along with how seamless the design process was implemented.