Thermo Fisher — Medical Laboratory Equipment

The Challenge: Simplify and better protect test samples during the process of withdrawing samples.

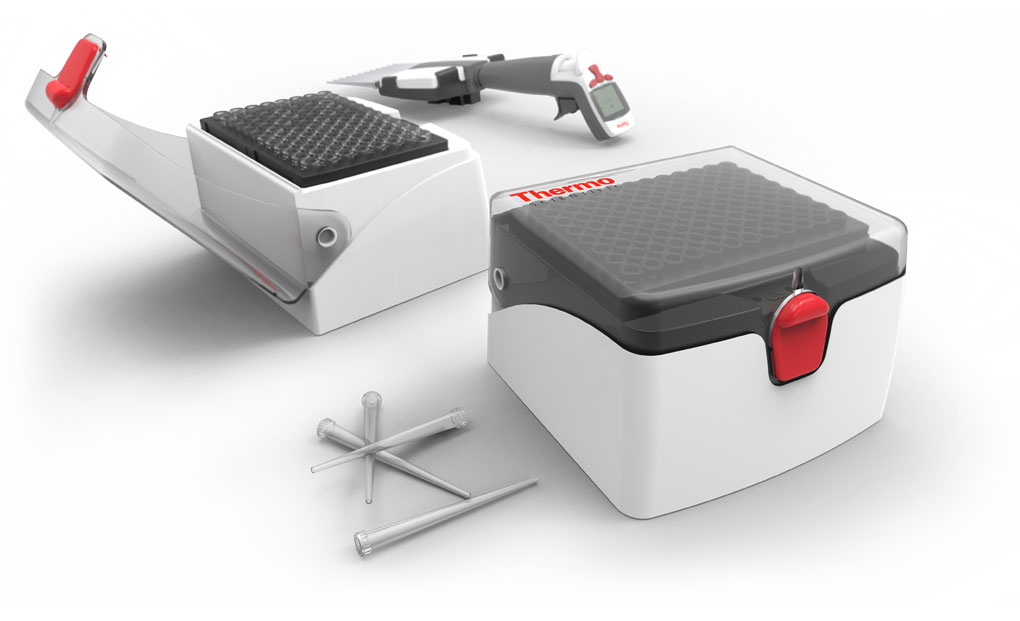

Traditionally, dispensing liquids through pipettes was done by hand. These methods often caused fatigue to the operator and were less productive. The bottom of the pipette should never touch the bottom of the microplate, which is difficult to achieve by human hand alone. By incorporating a linear guide rail, one or more pipettes can be accurately lowered into a solution tray with hard stops built into the fixture, consequently preventing the pipettes from bottoming out. Additionally, this system allows for up to 12 independent pipettes to be active in a single application, greatly increasing productivity.

A Study of Stability

Design Solution: Phase I

How Can We Take a Great Laboratory Tool and Make It Even Better?

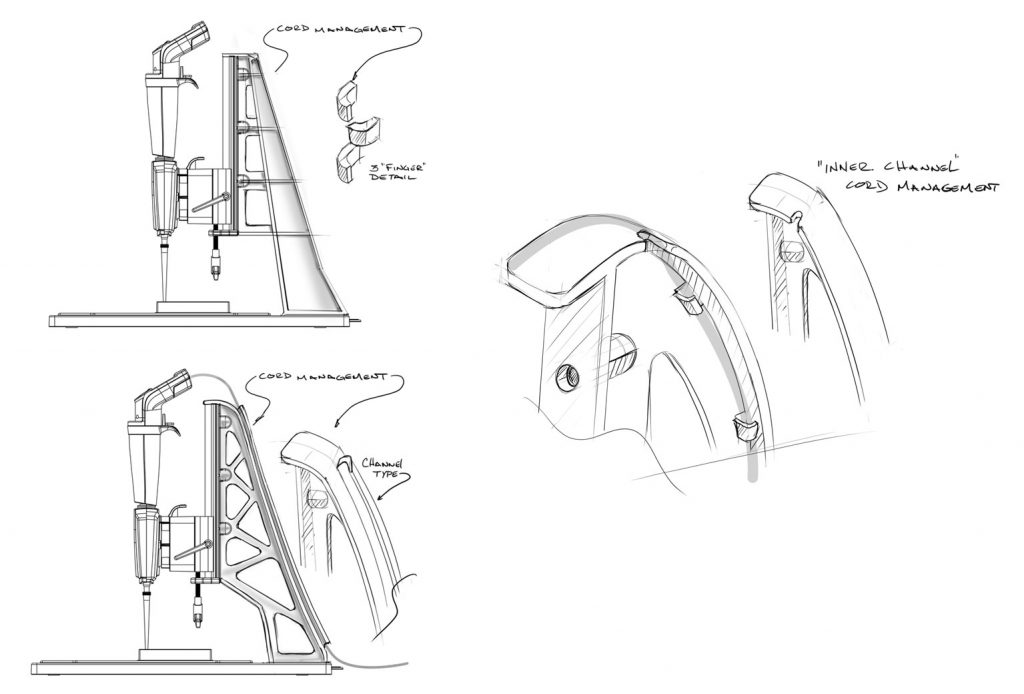

When we started looking at the multichannel pipette device, we first focused on the function of the slide ratchet rail and how to best construct it for stability and fluidity. It was important to avoid vibration and latteral movement. We studied conventional architecture and bridge design, along with other laboratory equipment currently in production, and compiled these studies into a variety of working ideation drawings.

3D Renderings

Design Solution: Phase II

An Economic Solution for the Dispensing of Liquids from Multiple Pipettes.

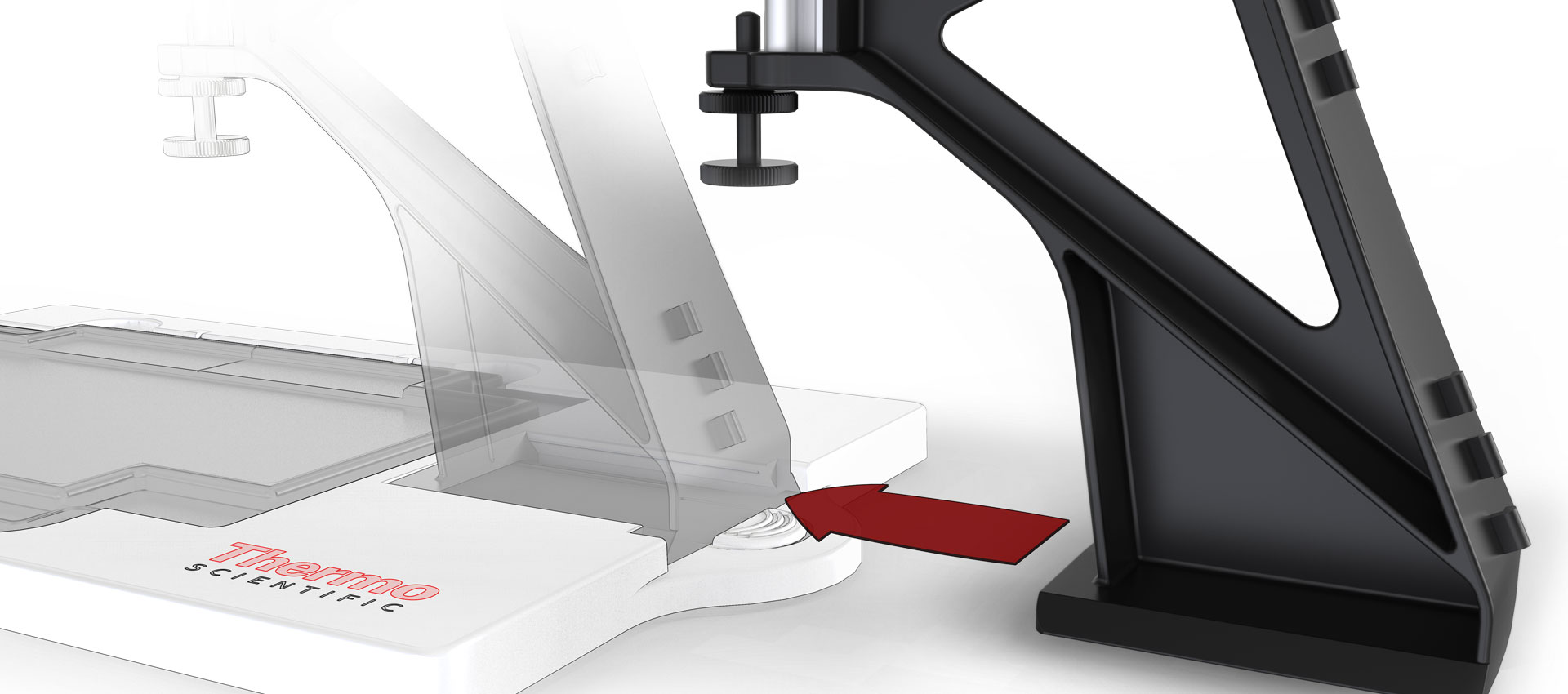

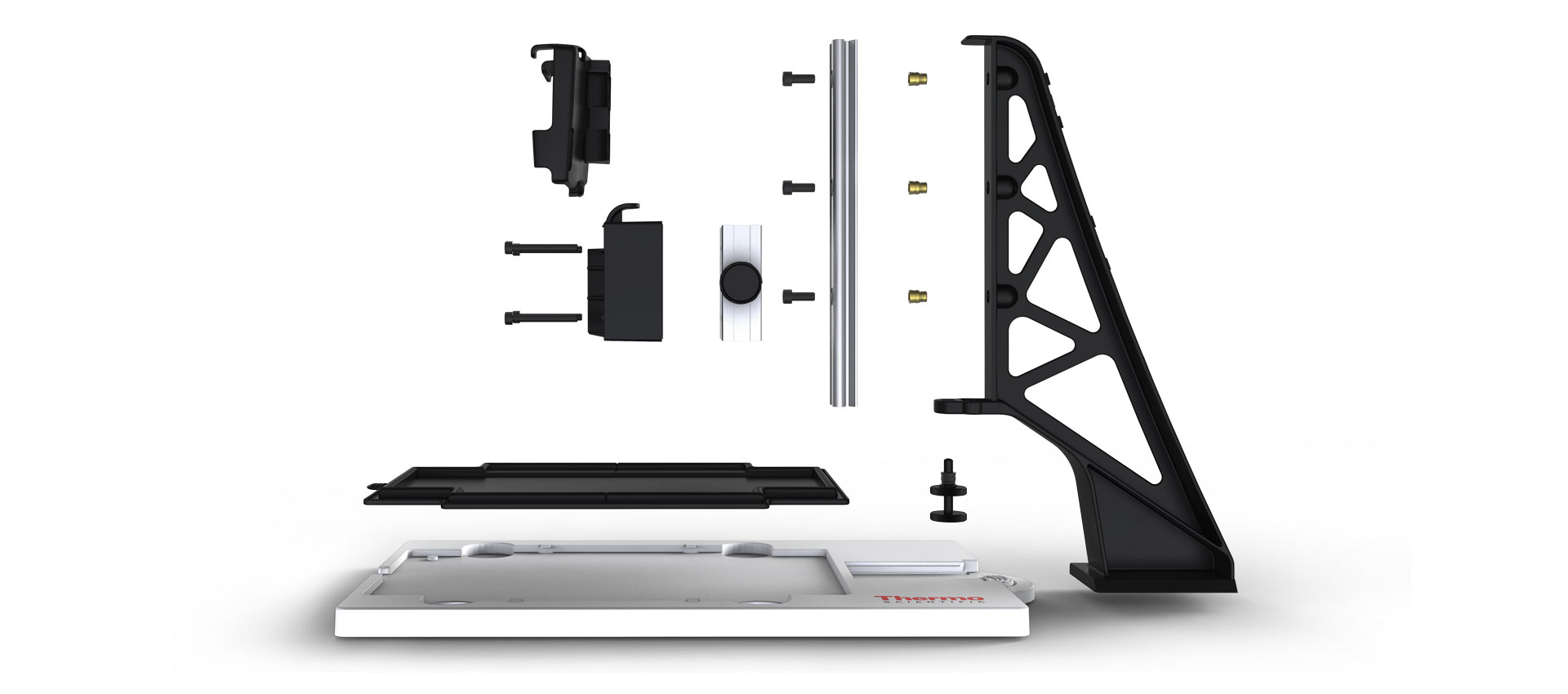

The the slide ratchet rail system — a feature that allows multiple pipettes to equally dispense liquid at the same time — had to be sturdy and rigid to prevent the misalignment of the pipettes entering the microplate. We concluded that by using a cross-rib, truss-like design, we could achieve a stronger backbone, while at the same time, reduce excess material, resulting in cost savings. The system includes an easy-turn ratchet system that allows for smooth and precise up and down movement of the Finnpipette™ Novus Electronic Multichannel Pipette device. Additionally, we designed a complimentary pipette storage case with an easy view protective lid, a removable surface tray for easy cleaning and integrated cord management for the electronic pipette device.

Prototypes

Design Solution: Phase III

Working Models are Essential for Testing Functionality Prior to Production.

Creating a functional model provides a useful and afforable way to engage with the product prior to manufacturing. This may prevent costly retooling as a result of late-stage design changes. Our 3D models are built to scale, strong enough to allow for common handling, without fear of damage. Models are critical assets to the design cycle, providing a suitable prototype that can be put into use for testing purposes.

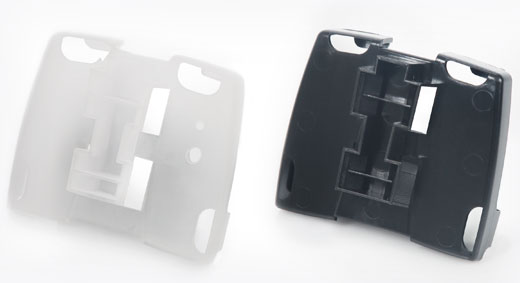

SLA MODEL: Backbone brace prototype detail study

POLYURETHANE MODEL with production pipette device holder

SLA MODEL: 3D printed pipette device holder

Final Product Design

Final Design Solution

Laboratory Product Design:

The Thermo Fisher Pipette System was a highly successful design execution. It not only offered an ecomomic benefit, but also provided a great amount of relief to the user by eliminating arm fatigue. We supplied all the necessary files and material specifications to immediately begin production. The system is currently being sold on thermofisher.com.